Welcome to JEMS DTTC - Direct Technical Training Center

We are not just a training center. We are a Beacon of Hope stationed right here, in the heart of the rural landscape, bringing Global Standards to local talent. We exist to bridge the massive divide between urban education and the raw, demanding reality of modern industry.

Mission

Now, through JEMS DTTC, Abhivi. Jagannathan M.R is bringing 40 years of global expertise back home. His mission is to turn the Youth of Today into the “Village Scientists” of Tomorrow Technically Sound, Practically Skilled, and Ready to Conquer the World, just as he did.

Vision

Our Vission is to unleash rural talent and mould them into global technocrats through practical innovation and industry expertise.

Training Carrier R&D Business

Skill is Money

Skill is Money

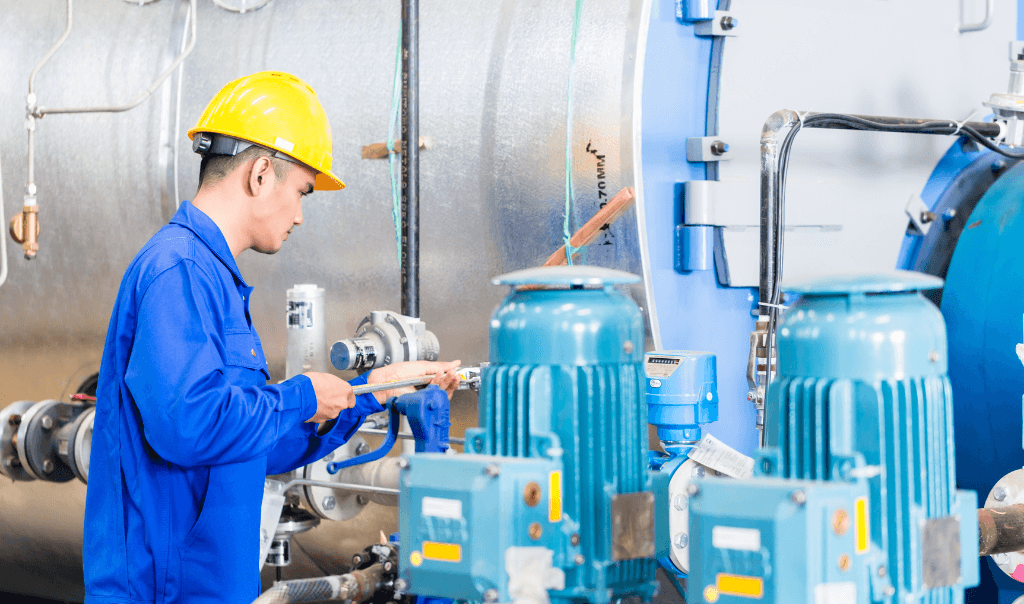

Hands-on Heavy Equipment Maintenance Training for High-Paying Jobs

Advanced PLC Automation and Medical Equipment Repair Course

Industrial R&D and Machinery Modification Consultancy for Startups”

Skilled Technical Workforce Recruitment for Construction and Marine Industry

Global Standard Vocational Training Center for Rural Entrepreneurs”

JEMS DTTC: Empowering the Future of Engineering

JEMS DTTC is a premier technical training ecosystem dedicated to closing the “skill-gap” in the modern engineering landscape. We provide Direct Technical Training (DTT) a methodology that skips redundant theory and focuses on the high-precision skills required by Industry.

Our mission is to transform passive learners into active problem-solvers, ensuring that every participant from student to entrepreneur emerges with a competitive, market-ready edge.

For Engineering Students: "The Industry Readiness Bridge"

The transition from a university classroom to a high-tech factory floor is often the hardest leap for a

For Job Seekers: "The Employment Accelerator"

For those entering a competitive job market, JEMS DTTC provides the "Trust Signals" and verified skills that

For Working Professionals: "The Upskilling Engine"

In an era of rapid technological displacement, JEMS DTTC ensures that a professional's career trajectory

For Entrepreneurs: "The Innovation & Scaling Partner"

Engineering startups face high risks. JEMS DTTC acts as a technical co-pilot to help founders build robust, scalable

1. For Engineering Students: "The Industry Readiness Bridge"

The transition from a university classroom to a high-tech factory floor is often the hardest leap for a student. JEMS DTTC makes this seamless. It ensures you don’t enter the market with “Expired Skills.” You migrate from a “Fresher” status to an “Advanced Technical Asset” even before your first job.

Skill Transfusion : (The Training): Intensive hands-on modules where trainees work on high-end equipment to bridge the technical gap.

Hands-on Lab Immersion: Moving beyond textbooks to work with real-world PLC systems, CNC machinery, embedded systems, and advanced Technology.

Final Year Project Support: Technical guidance for academic projects, focusing on building functional prototypes that solve real industrial problems.

Standard Operating Procedures (SOP): Training in industrial discipline, including safety protocols (PPE), documentation, and reporting standards used in multinational companies.

Logic & Diagnostic Foundation: Developing the cognitive “troubleshooting” mindset required to identify system failures before they become costly.

2. For Job Seekers: "The Employment Accelerator"

For those entering a competitive job market, JEMS DTTC provides the “Trust Signals” and verified skills that recruiters demand.

Skill Harmonization: Custom training modules that align a candidate’s degree with current high-demand vacancies (e.g., training Mechanical Engineers for EV Battery Design).

Industry Simulations: Mock industrial scenarios where candidates handle high-pressure troubleshooting and technical decision-making.

3. For Working Professionals: "The Upskilling Engine"

In an era of rapid technological displacement, JEMS DTTC ensures that a professional’s career trajectory remains upward.

Industry Migration: strategic process of moving an individual’s or a company’s skill set, technology, and operations from traditional, legacy engineering paradigms to modern, high-tech frameworks

Niche Specialization: Transitioning general engineers into Subject Matter Experts (SMEs) in fields like Mechatronics, Cyber-Physical Systems, and Renewable Energy.

Lean & Six Sigma Implementation: Providing the tools to reduce waste, optimize supply chains, and increase the ROI of their current employer’s operations.

Non-Logic Diagnostic Training: Advanced training for senior technicians to identify “invisible” failures through heuristic patterns, sound, and historical data patterns.

4. For Entrepreneurs: "The Innovation & Scaling Partner"

Engineering startups face high risks. JEMS DTTC acts as a technical co-pilot to help founders build robust, scalable businesses.

Rapid Prototyping Access: Access to specialized labs for building MVPs (Minimum Viable Products) without the need for massive upfront capital investment in machinery.

Technical Literacy for Management: Empowering non-technical founders to understand engineering logic, allowing them to manage technical teams, set realistic deadlines, and control costs.

Process Standardization: Consulting on how to design repeatable, high-quality manufacturing or service processes that maintain integrity as the company scales.

Risk Mitigation: Training in failure mode analysis and technical compliance to ensure products meet international safety and quality standards.

Why Choose JEMS DTTC?

Direct Technical Training (DTT): We don’t just teach; we demonstrate. Our instructors are industry veterans, not just academicians.

State-of-the-Art Infrastructure: Access to the same equipment used by global engineering leaders.

The Diagnostic Advantage: Unique focus on both Logic and Non-Logic troubleshooting, making our trainees the most sought-after “Fixers” in the industry.